The chemical composition of the battery manufacturing process is a time-consuming process that involves multiple charges and discharges to activate the battery chemistry, which is particularly critical to ensuring the consistency, safety and high quality of the power battery pack for a long cycle life. In order to improve the electrochemical performance of the battery, such as cycle life, stability, self-discharge and safety, the consistency of the battery must be strictly controlled and the grade of the battery must be accurately evaluated, so the measurement accuracy of the chemical capacitance testing equipment is put forward a high requirement.

Open circuit voltage, end voltage, internal resistance, specified process capacity, energy, charge and discharge efficiency, step time, fixed point capacity, median voltage of self-discharge rate, constant current percentage, etc. The battery can be more accurately graded for the number of passengers.

Over and under current, over and under voltage, capacity, reverse connection, misconnection, trend anomaly, pulsation anomaly, wave protection, differential pressure and other protection, protection mechanism is complete, and the test process is safer

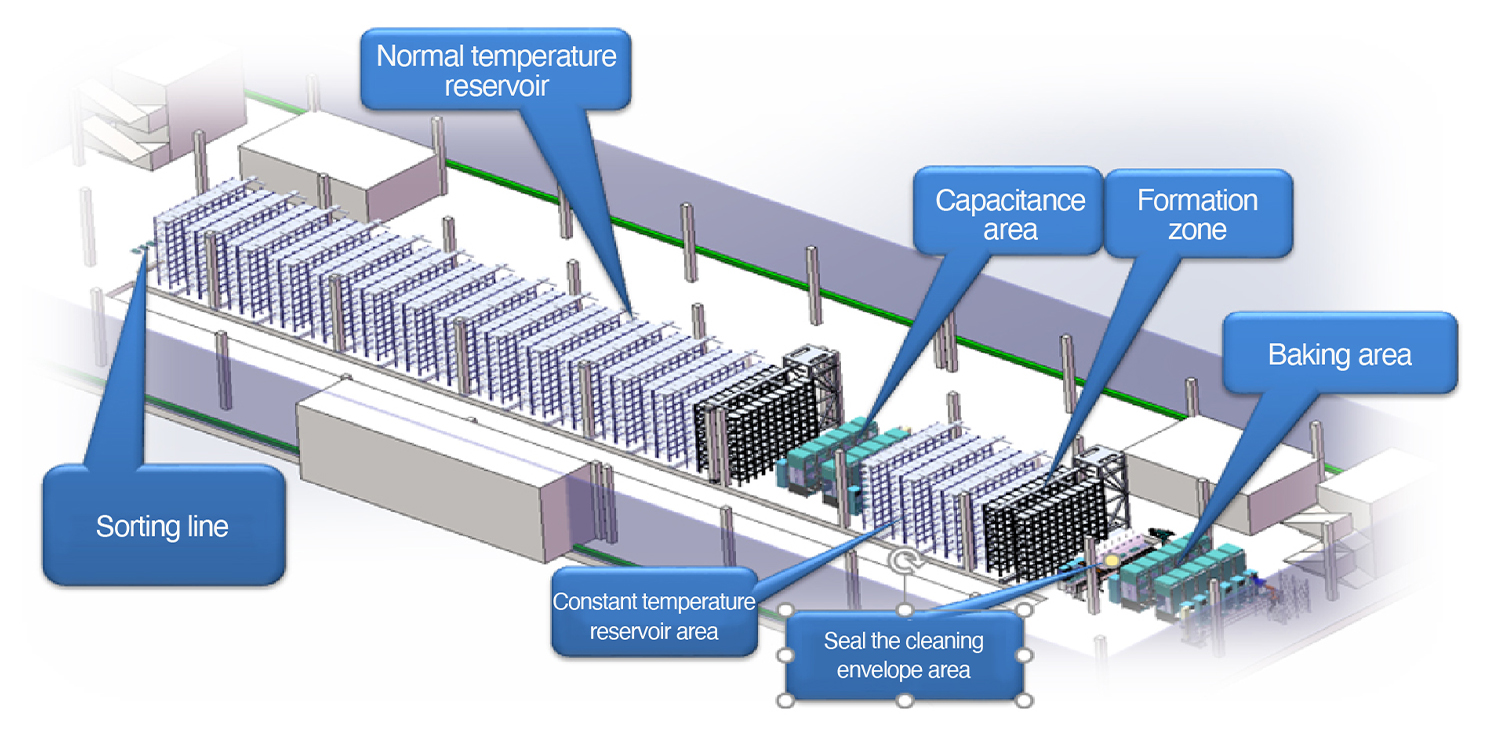

Including formation, automatic sorting, automatic line, AGV, OCV, DCIR test, three-dimensional warehouse, assembly and other complete production process; High degree of data integration: the production process can be traced and the scanning code can be started. MES database system can be unattended to improve production efficiency

Automatic line can be customized according to customer needs